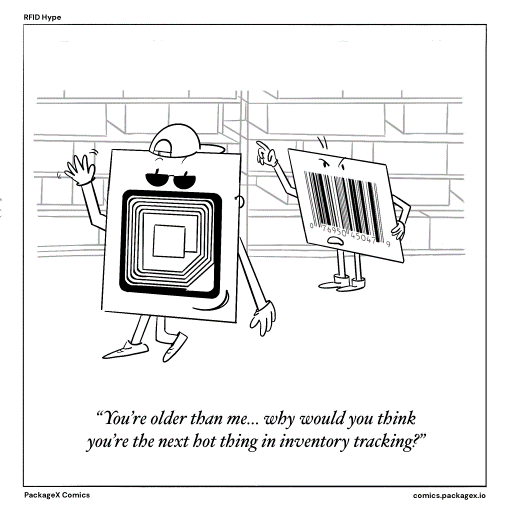

RFID Hype

RFID was first used during WWII but claims to be the new technology retailers need. Meanwhile, barcodes are newer, cheaper, and as effective for powering logistics operations.

Every year, companies claim that “this year is the year for RFID technology.” Turns out, these are the same companies that sell RFID, a technology initially used by the British during World War II to distinguish enemy aircraft from ally aircraft.

The system was called Identify Friend or Foe (IFF). Using this system, British planes would transmit a coded signal to radar towers. If the radar picked up the signal, ground troops would hold their fire. If no signal were read, the sky would be blasted black with flack, and foes would fall from the sky.

This initial use case of RFID presented a simple solution to a serious challenge. Then, after the war, what qualified as “serious” began to change. In the post-war world, commerce became a serious business. Allies resumed regular trade, and enemies slowly became new friends to trade with.

According to the World Trade Organization, world trade volume today is roughly 45 times the level recorded in the early days of the GATT, achieving 4500% growth from 1950 to 2022. (GATT stands for the General Agreement on Tariffs and Trade, an agreement between countries to promote international trade by reducing pre-war trade barriers such as tariffs or quotas.)

When global trade started its massive ascension after the war, research on the barcode began — specifically for retail. Just before global trade achieved hockey stick-like growth in the 1990s, the United States required vendors to use UPC barcodes for inventory management.

The barcode became the de facto technology for achieving affordable, efficient inventory management, which remains true today. However, since there’s more trade and products than ever, the way to acquire data about products and parcels must change.

To address the need for optimal efficiency and accuracy in inventory mangement, major retailers like Walmart started using RFID technology in 2005. Other retailers started using it primarily for theft control. Similar to the IFF use case during World War II, people exiting the store with unpaid-for products would trigger a “foe alarm” at the door.

However, you might have noticed that the door alarms have started disappearing over the years. Or, at best, they have only acquired slow adoption in certain locations for certain retailers. That’s because RFID technology is expensive. Often too expensive to make sense. This is especially true for logistics use cases.

Depending on features and capabilities, RFID tags used in logistics and supply chain management can range from $20 to $50 or more per tag. (source)

This makes computer vision technology that can read barcodes, identify parcels based on shape and size, and instantly acquire other information on parcels like bill of lading slips particularly interesting to retailers. Unlike RFID technology, which requires expensive tags, computer vision technology uses what’s already on the box or product.

However, one technology company is building retail solutions with both computer vision and RFID. Radar is a hardware and software platform that uses RFID and computer vision to locate in-store inventory. Its technology is used in stores across the U.S. and services 500 American Eagle locations.

Radar pledges to finally live up to the hype of RFID, but for in-store use cases. Their solution doesn’t solve any problems with the movement of goods outside of the store — aka logistics. That’s because solving logistics problems with RFID is (you guessed it) expensive. It would also require everyone across the whole chain to agree to use RFID, from manufacturer to shipper to seller.

A much better approach is visually identifying the item and skipping the expensive RFID step altogether. Retailers can use the inexpensive barcodes they’ve been using and, combined with computer vision, achieve the same magical inventory management experience by feeding data into a pure AI scanning model built for logistics.

We’re not saying RFID isn’t useful technology, but until its price plummets and all supply chain partners agree to adopt it, RFID will continue to be an old dog trying to learn new tricks.